The sky’s the limit with thermal spray coatings from Thermaspray

HVOF (High Velocity Oxy Fuel) thermal spray coatings available from Thermaspray, are used to protect the external high strength low alloy steel surfaces of aircraft landing gear components against corrosion and wear.

During landing and taxiing, an aircraft’s landing gear is subjected to a great deal of stress, side-loading and sliding wear. Any coatings applied to protect these large hydraulic units from wear resistance and corrosion must be of first-class standards to be able to withstand these stresses. Until recently, electrolytically deposited chrome plating was the standard surface treatment for landing gear components which are critical safety components on an aircafrt.

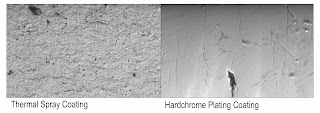

According to Metallurgical Engineer at Thermaspray, Shaik Hoosain, hard chromium coatings have been the gold standard to impart resistance to component wear, impact and corrosion in aviation, transportation, industrial and consumer products for more than 70 years. “While chrome has proven to be a relatively cheap and effective solution, chrome plated components are typically plagued by a debit in fatigue performance, detrimental mud cracking surface pattern, susceptibility to scoring, wear, and seal leakage. As these performance limitations are safety critical issues, environmental legislation has, not surprisingly, forced the aerospace industry to design the next generation of aircraft to be ‘hard chrome plating free’. The engineering community in both the military and civilian aerospace sectors, as well as in many industrial sectors, have been searching for better coating materials to replace electrolytically deposited chrome plating as well as for more cost-effective application methods.

Thermal spray coatings outperform hard chrome coatings in a number of vital areas and were found to be the perfect surface coating solution. Wear tests conducted on different hard chrome plated samples and HVOF thermally sprayed samples showed that fatigue and wear resistance of thermal sprayed coatings were superior to hard chrome. Test data confirmed that tungsten carbide, chrome carbide and chrome oxide HVOF coatings can last three to five times longer than hard chrome plating.

Thermal sprayed carbide based materials are commonly used for their exceptional hardness and have been employed for the surface treatments of parts that require a hard surface in wear interfaces. Chromium carbides are hard and their general use is to provide hard, wear and corrosion resistant coatings on parts that need to be protected. Chromium carbide-based coatings also do not suffer from effluent disposal problems. “They are therefore finding increasing use at the expense of hard chrome plating particularly where wear and corrosion resistance is important or if a thick coating is required on a large part,” affirms Hoosain.

According to Hoosain, thermal spray coatings are also significantly denser than chrome plated coatings. “The chrome plated micro-layer is filled with micro-cracks which allow corrosive agents with high or low pH to penetrate the coating and attack the substrate. If the substrate is ferrous, it can lead to severe corrosion of the substrate and ultimately coating failure. In addition, the thermal spray process is more versatile in terms of the type of coatings that can be applied compared to the hard chrome plating process which is limited to only one type of coating. “

HVOF thermal spray coatings eliminate all environmental issues and health concerns associated with electroplated hard chrome coatings as the hard chrome process has a significant negative environmental impact. Disposal of manufacturing wastes and by-products into uncontrolled surroundings and the subsequent health and environmental effects have been well documented and has resulted in hard chrome plating materials such as hexavalent chromium to be highly regulated and in some cases even banned (Europe and USA).

Thermal spray coatings outperform hard chrome coatings in the following ways:

• Increased wear resistance and service life

• Improved corrosion resistance

• Better bond characteristics

• Bonds to a wider range of materials

• Higher hardness

• Thick coating capability

• No part size limitation

• Does not affect the substrate

• No substrate fatigue debit

• No hydrogen embrittlement of substrate

Thermal spray coatings such as HVOF are an innovative, environmentally friendly, versatile and cost effective solution for high stress applications that require protection against wear and corrosion.

HVOF is complemented by Thermaspray’s comprehensive range of industry-leading spray coating solutions that include Plasma, Arc Spray, Spray Fuse, Power and Combustion Flame Spray. HVOF tungsten carbide coatings applied by Thermaspray have been approved by Sulzer in Switzerland.

Thermaspray, in a joint venture with Cape Town-based Surcotec, offers an extensive portfolio of engineering and thermal spray coating solutions that extend component life cycles to assist OEM and end-user clients across southern Africa in reducing costs and increasing production. The companies’ world-class quality wear- and corrosion-resistant thermal spray coatings, Plasma Transferred Arc (PTA) cladding and Polymer coatings (in partnership with Plasma Coatings USA and Diamant Metalplastic Germany) are augmented by a host of specialised allied services.

About Thermaspray

Thermaspray, headquartered in Olifantsfontein, Johannesburg, has close to 20 years’ experience in wear- and corrosion-resistant thermal spray coatings. In addition to providing a comprehensive range of support coating finishing technologies in the bespoke finishing shop, Thermaspray also refurbishes industrial components damaged by wear and corrosion. The company’s in-house, metallurgical laboratory is the only dedicated facility of its kind in Africa’s thermal spray industry and is equipped to undertake world-class developments and quality control. Thermaspray is a DQS ISO 9001 Quality Management and Eskom level 1 certified company. www.thermaspray.co.za

About Surcotec

Surcotec is the oldest established thermal spray coating company in the Western Cape. The company has a wealth of experience in thermal spray coatings and mechanical component refurbishing. Surcotec’s coating services are supported by a fully equipped engineering workshop and an on-site machining division. A level 1 B-BBEE company, Surcotec is TNV ISO 9001 Quality Management certified and is certified as a level 2 nuclear supplier to Eskom. www.surcotec.co.za

Issued on behalf of: Thermaspray

3 Axle Drive, Olifantsfontein, Johannesburg.

Tel: +27 (11) 316 6520/8/9 / Fax: +27 (11) 316 7527

Blog: http://thermal-spray.co.za/blog/

YouTube: www.youtube.com/thermaspray

Media Contacts: Dr Jan Lourens – Managing Director

jlourens@thermaspray.co.za

Mariette Broodryk – Marketing Assistant

mbroodryk@thermaspray.co.za

By: Sonia Laverick – Laverick Media Communications

Tel: +27 (11) 0400 818 / Fax: +27 (86) 671 6836

lavmedia@iafrica.com / www.laverickmedia.co.za

Thank you for your informative blog on I hvof coatings. That is quite beneficial to us.

ReplyDeleteThank you for sharing such wonderful information about thermal spray coating

ReplyDeleteThis article has good content. I appreciate you giving this vital thermal coating spray information.

ReplyDeleteThat's really awesome blog because i found there lot of valuable Information. Great articles love it good work keep it up.CNC Machining KS

ReplyDelete